Optimizing for weight and recyclability

Plastic traditionally offers valuable weight advantages,but is a challenging waste stream to recycle. For our packaging, we’re leveraging the ubiquity of paper recycling and focusing on fiber-based solutions instead.But lighter materials are preferred, and when we couldn’t quite find a paper to match our protective quality needs that also minimized weight, we made one.

Collaborating for innovation

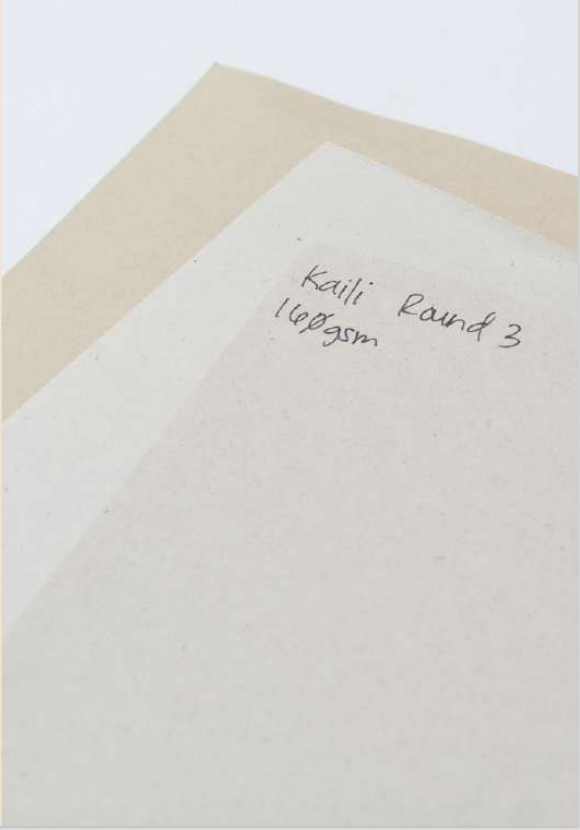

Together with Veritiv and Google, we created a custom paper that raised the bar on several key requirements. Ultimately, our collaboration pushed the limits of what paper could do.We specifically designed for tensile energy absorption (TEA) and stretchability. We defined Critical to Quality (CTQ) parameters for cosmetic performance, functional packaging performance, stretchability, surface strength,bending moment, and folding endurance. After multiple iterations, we created a custom formulation with an optimal fiber blend ratio and pulp refining parameters that met our CTQ targets for both cosmetic and functional packaging performance and successfully scaled up to mass production of our product portfolio.Our new paper recipe is three times stronger and 70% more stretchable than our previous paper. It enabled us to use less material and create a lighter, more efficient packaging solution without sacrificing product protection. The lower packaging weight reduces the carbon footprint of transportation compared to our previous design.